The Phytobac® Modules

Every farm has its own requirements regarding the cleaning of agricultural machinery. With the Phytobac® system, you can decide which modules, size, or model is best for your farm.

You can order all Phytobac® modules directly via Beutech. Other components such as high-pressure cleaners, crop protection containers, wash basins or oil traps are available on request from our partner companies.

Tip: Save installation costs by using your own equipment and take on the preparation of the washing area and the final installation of the Phytobac® yourself.

easyFlow

easyFlow is the first closed and thus contamination-free transfer system for transferring liquid crop protection products from open or sealed containers into sprayers. The system allows you to partially or fully empty containers and rinses itself, as well as the used containers in the process.

easyFlow

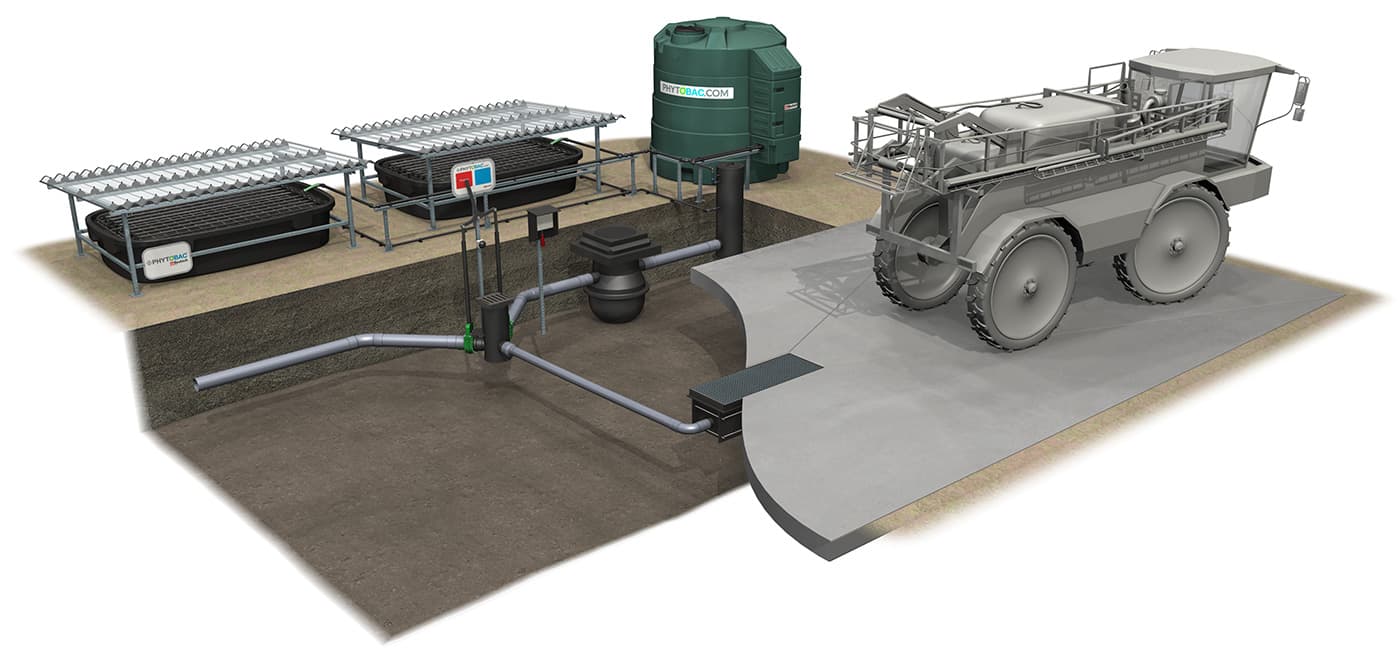

Washing Area

The contaminated wash water from cleaning the spraying equipment must be securely collected and not percolate into the ground. Therefore, the concrete slab is impermeable and bunded?. The requirements are equivalent to those for silo or dry stack flooring. Please discuss this during the consultation and talk to your local architect.

Substrate Container

The Phytobac® substrate container consists of an impermeable container with a height-adjustable rain roof, an inspection tube, and a pre-mounted drip and drain pipe.

For the substrate, simply mix biologically active soil from your farmland with straw. The soil naturally contains micro-organisms which degrade crop protection residues. Sensors and the fully automated control system keep the substrate moist. The micro-organisms can thus degrade the residues from the wash water under optimal conditions, and the clean water evaporates from the surface.

Control System

The control unit with sensor monitors the optimal degradation and evaporation conditions in the substrate. The regulation of the appropriate sprinkling frequency is fully automated.

The CE marking fulfils the EMC norms 2006/95/EG (EN 6100-6-1/3).

Buffer Tank

The amount of contaminated wash water varies considerably during the spraying season, as does the evaporation rate in the substrate container. Hence the contaminated water is temporarily stored in the impermeable buffer tank and is sprinkled onto the substrate as needed.

The tank is double-walled and thus leak-proof. The fitted box contains the control system, the filter, and other connectors. Anti-frost protection and a mechanical level indicator guarantee the system’s functionality. The buffer tank can be supplied in five different sizes depending on your farm’s requirements.

Sump-Pit

The contaminated water from the washing area and the excess drainage water from the substrate container flow into the impermeable sump-pit. The water is pumped into the buffer tank via a stainless steel sump-pit pump. A safety shut-off prevents the buffer tank from overflowing.

Safety Sludge Trap

The sludge trap ensures that the operation of the Phytobac® system is not compromised by soil and dirt. The system is installed in front of the sump-pit.

Switch

The switch allows you to select between the two required water circuits: The contaminated wash water is directed into the buffer tank and automatically sprinkled onto the substrate. Effluent rainwater or clean wash water can be directed into a sewer, a draining ditch, or a biotope. You operate the switch with a lever which always indicates the desired drainage direction.

Pre-Sludge Trap in the Washing Area

Washing areas for agricultural machinery contain a high proportion of soil. The pre-sludge trap at the washing area reduces the wash water’s flow rate, and foreign matter (soil, stones) conveniently settles on the bottom of the storage space. The module is covered with a heavy-duty grate accessible by vehicle. The pre-sludge trap can be easily cleaned using a flat shovel and a wheelbarrow.